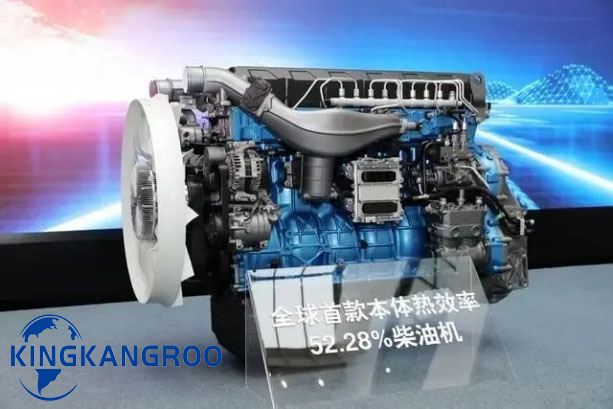

On the afternoon of November 20, 2022, Weichai released the world's first commercial product of a diesel engine with a body thermal efficiency of 52.28% and a natural gas engine with a thermal efficiency of 54.16%, and passed the novelty search certificate of the Southwest Research Institute of the United States. With three breakthroughs in thermal efficiency in three years, Weichai stands at the top of the world in the field of thermal efficiency of internal combustion engines.

So, what does this breakthrough mean for the construction machinery industry and its users, and what impact will it bring?

What is bulk thermal efficiency? What are the benefits of increased thermal efficiency?

First of all, we need to understand what is thermal efficiency. It is well known in the industry that the engine relies on the combustion of fuel to do work, and the heat generated by the combustion is used to drive construction machinery such as excavators, which is a process of converting heat energy into mechanical energy.

However, it is impossible to achieve 100% complete combustion of fuel, and the engine also has intake and exhaust losses, mechanical resistance, etc., so only a part of heat energy can be converted into final mechanical energy. The ratio of this conversion is the thermal efficiency. For example, the usual thermal efficiency of 46% means 10L of oil, and only 4.6L of oil is really used to drive the excavator construction work.

The thermal efficiency of the body refers to the ratio of converting the energy of diesel combustion into the effective output work of the engine without relying on the waste heat recovery device. So the conclusion is that the higher the thermal efficiency of the internal combustion engine body, the more fuel-efficient the equipment with the same configuration, the less oil used for the same project, and the less emissions. It is truly energy-saving and emission-reducing, thereby realizing the dual benefits of economy and environmental protection.

"Compared with the industry average, a diesel engine with a thermal efficiency of 52% can reduce carbon dioxide emissions by 12%, and a natural gas engine with a thermal efficiency of 54% can reduce carbon dioxide emissions by 25%," said Tan Xuguang, director of the State Key Laboratory of Internal Combustion Engine Reliability and chairman of Weichai Power. If all two Weichai engines are commercialized, they can reduce my country's carbon emissions by 90 million tons per year, which will greatly promote my country's energy conservation and emission reduction.

Three breakthroughs in three years, the industry structure is being reshaped

Leading thermal efficiency technology is profoundly rewriting the existing pattern of the market.

Weichai broke through 50.23% in 2020 and 51.09% in January this year. Now it has once again set a new global record of 52.28%, and has reached the peak of the world industry for three consecutive times. And with the commercialization of Weichai, it is also bursting out a significant market effect.

According to reports, after the thermal efficiency of the diesel engine itself exceeded 50.23% in 2020, Weichai began to gradually apply high thermal efficiency technology to commercial engines in large quantities, with remarkable results.

Among them, in the field of heavy trucks, Weichai's H-series and T-series engines, which will be launched in 2021, have outstanding fuel-saving performance. Compared with international competing products, the fuel-saving per 100 kilometers can reach 2L. The increase in fuel efficiency brings about an increase in market share. Weichai's heavy truck market share in 2021 will be 31.7%, and it will reach 32.2% from January to October in 2022, and it is expected to be close to 33% for the whole year.

In the field of construction machinery, Weichai will sell about 200,000 engines for construction machinery in 2021, a year-on-year increase of 15%. In the excavator market, it has achieved double growth, with breakthroughs in small excavation, medium excavation and large excavation; in the market of 3 tons and above loaders, Weichai has a market share of about 80%; in the truck crane market, Weichai's market share is about 65%, and all truck cranes over 300 tons have been replaced by imports; in the wide-body dump truck market, Weichai's engine market share is about 83%. It is expected that in 2022 Weichai will have greater breakthroughs in various segments of construction machinery.

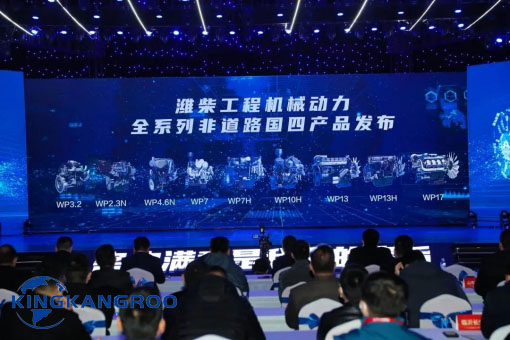

Non-road country IV, Weichai is more fuel-efficient

In response to the full implementation of non-road China IV emission standards on December 1, 2022, Weichai has also made arrangements ahead of schedule. As early as December 2021, Weichai took the lead in releasing a new generation of "N+H" full series of non-road national IV products, covering 9 products including WP2.3N and WP3.2, with a total of 13 rows from 2.3L to 17L The power is fully covered from 36.8kW to 566kW. It has five major characteristics, such as "everything is complete, safe and reliable, efficient and fuel-efficient, adaptable to the environment, and intelligent electronic control", which makes Weichai stand out from the competition with competing products.

In December 2021, Weichai will release a full range of non-road China IV products

According to reports, Weichai’s non-road National IV engines save more than 10% of fuel compared to National III engines. Taking excavators as an example, on the basis of the commercialization of thermal efficiency technology, Weichai has built a hydraulic power assembly to reduce the overall fuel consumption of the matching machine by 15%, and the efficiency can be increased by 10%. Dressup provides a solid foundation.

Actively deploy new energy sources to support the dual-carbon strategy

Under the target strategy of "carbon peaking and carbon neutrality", continuous improvement of engine thermal efficiency and reduction of energy consumption is an important way to achieve the goal, while the development of new energy is another important direction.

Since 2010, Weichai has successively invested 4 billion yuan in the layout of new energy business, and built the world's largest R&D and manufacturing base of 20,000 hydrogen fuel cell engines. Relying on the National Fuel Cell Technology Innovation Center, seize the major opportunity of the "Hydrogen into Thousands of Homes" technology demonstration project, actively deploy a full range of commercial vehicle hydrogen power, and launch a series of mature and tested commercial products, which are China's hydrogen fuel The battery commercial vehicle is a veritable leader.

In the face of the transition from traditional energy to new energy, Weichai has also considered the issue of energy diversification. While promoting the commercialization of hydrogen power, it is also actively deploying new energy technologies such as pure electric power, hybrid power, methanol engines, and ammonia engines. route. Weichai's layout in new energy and the continuous development of traditional business are complementary, and will also bring more diversified choices to the construction machinery industry.

The technological revolution has boosted industrial transformation, and precise efforts have been made to promote structural adjustment. Every breakthrough of Weichai has brought infinite surprises to the industry and infinite possibilities for industrial transformation. In the face of a complex and ever-changing future, we expect Weichai to continue to lead the industry in the new round of development with excellent technology, products and high-quality services, and to contribute to the high-quality development of China's construction machinery industry with a strong "heart".